From Ryan Kennedy at pv magazine USA:

The Solar and Fire Education (SAFE) program, an initiative led by retired Las Vegas Fire & Rescue Captain Richard Birt, has released new survey data regarding first responder preferences for rooftop solar inverter architecture.

The program, which provides hands-on training to help fire departments navigate the complexities of modern energy systems, found that after receiving specialized education, more than 98% of participating firefighters said they recommend microinverter-based solar energy systems.

This is a bullshit survey, and a bullshit article.

I saw this first through pv magazine, but it comes from Enphase highlighting it in a press release.

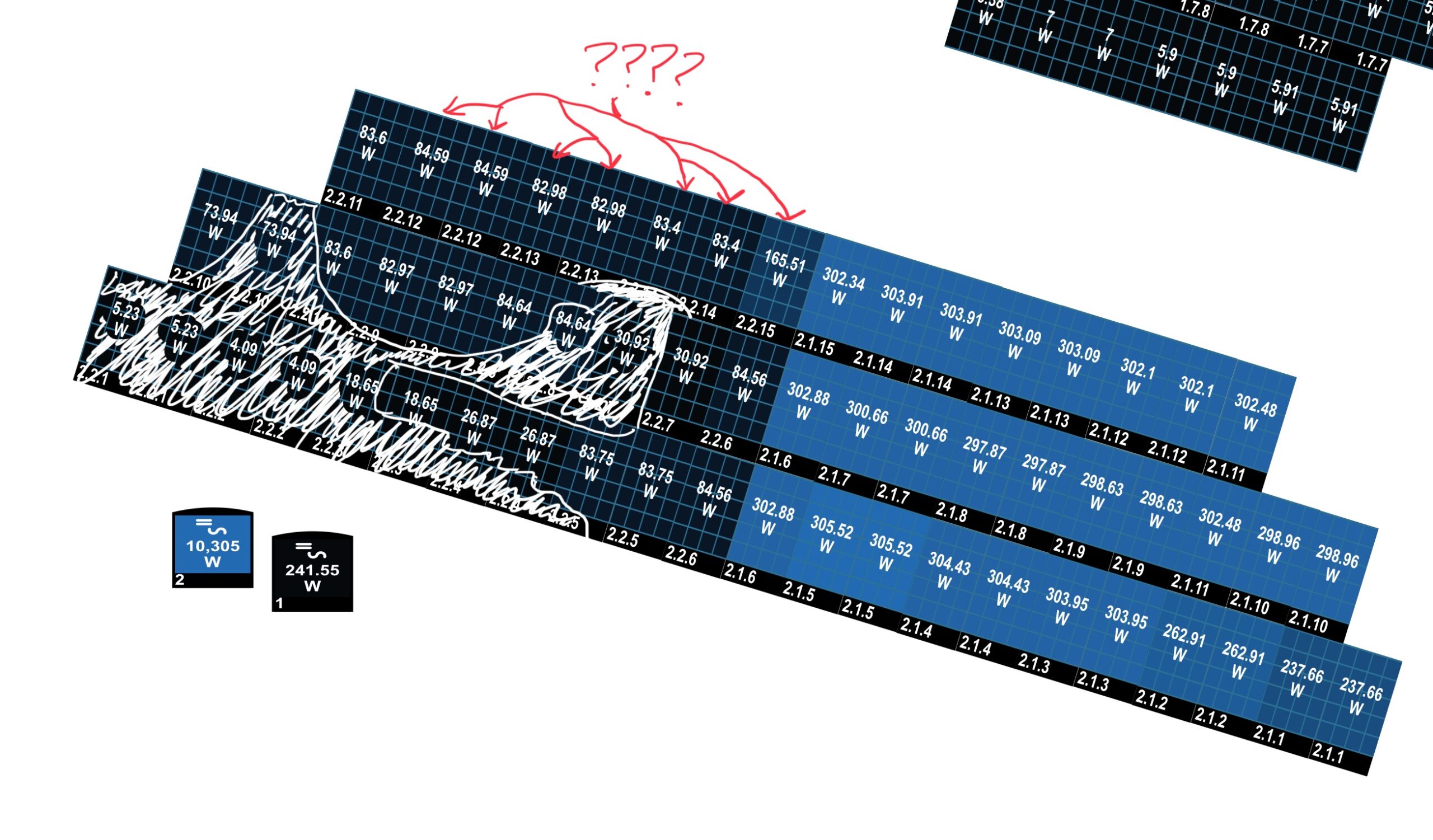

Here is the original survey information, pulled from the Solar and Fire Education website.

Important things to note:

- Captain Richard Birt, the owner of SAFE, is a long-time proponent and, safe to say, propagandist for AC microinverters, if you listen to literally anything he has to say, ever.

- Captain Richard Birt is a paid consultant of Enphase, and Enphase collaborates with him in his training.

- There were only five questions asked.

- The questions were asked immediately after a SAFE training.

- The only eligible firefighters that were allowed to take this survey were those who took a SAFE class and chose to voluntarily respond.

- There were only “200+” firefighters who responded.

- Respondents received a plain-language description of string inverter and microinverter architectures and were asked which they considered safer for homes and businesses.

- There is an entire page dedicated to important limitations and disclosures, wherein SAFE themselves assert that the survey is far from scientific and should not be taken as representing all firefighters or as independent scientific proof of microinverter safety.

Nothing here warrants any consideration, but here’s a couple of comments from me anyway:

- Logically, most people choose the most impressive number they can when reporting these numbers. If there were 254, for instance, they’d say 250+. I’m guessing we’re in the low 200s here, far from an adequate sample size, even if the questions were legit.

- Five questions is hilarious. We aren’t privvy to the nature of the questions, but I’d imagine they aren’t remotely rigorous. Especially since the descriptions were of string inverters, no mention of RSD systems or optimizer systems.

- Clearly the SAFE training was teaching with the idea of getting people to answer the “right” thing on a survey afterward.

- This should be extremely obvious, but ALWAYS treat with extra rigor any data or whitepapers that come out in support of the company that is promoting them.

Jim Foran, Director of PVSTOP, a spray for suppressing solar panel voltage in an emergency, also had this to say about SAFE:

PVSTOP was approached by Richard [Birt], who discussed including PVSTOP in his presentations If we agreed to pay him. We respectful[ly] declined – not the way we roll.

We’d rather rely on the evidence based data provided by a growing number of world leading Fire Departments who actively deploy our products to de-energise PV Systems at source and genuinely improve firefighter and first responder safety.

Now, about pv magazine — the way their article was written originally questioned nothing about the press release, and basically just rewrote it and published it. Most other financial and industry outlets published the press release as an Enphase press release. Since then, there has thankfully been a couple changes, noting the financial relationship between Enphase and Captain Birt.

Regardless, this opening headline is still doing exactly what Enphase was hoping this would accomplish. The politics of solar safety, paired with firefighter fear, is alive and well, stoked by the ignorance of folks like Captain Birt.

I don’t have anything against firefighters, truly. However, our industry has been attacked again and again by those who don’t know enough about electricity to make safety decisions. Firefighters are important to bring into the fold and teach about electricity, but so often we have the blind leading the blind. Rapid shutdown itself was not introduced with any data supporting that firefighters have ever had electrical accidents with solar, yet we still so often need to pay the ransom to Enphase, SolarEdge, Tigo, etc. to get rooftop solar built in this country at all.

Electrical safety should be taught in partnership with electricians with a solid understanding of theory, not by retired fire chiefs with an ax to grind.

Disclosure: I run The 3741 Reference, and have a long-documented dislike of rapid shutdown. I’ve also received product from PVSTOP in the past for testing and review purposes.